Anyone picturing an ordinary automotive garage would be mistaken. A Formula One team’s garage functions far more as a traveling technical laboratory than a maintenance bay.

Situated on the first floor of the Paddock club, directly along the pit lane, it is the site of three-second tire changes and the center of each team’s operational and engineering activity. Security is stringent: public access is prohibited, and photography or video recording is not permitted.

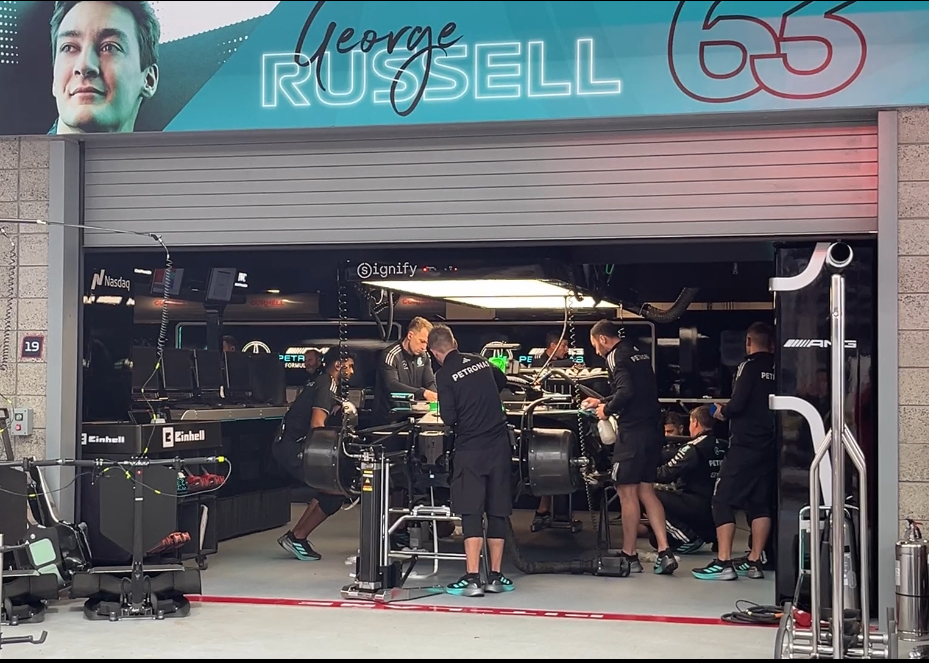

On November 20, The Korea Daily was granted access to the Mercedes-AMG Petronas F1 Team’s garage during the 2025 F1 Las Vegas Grand Prix.

At the center of the workspace stood the cars of George Russell — last year’s Las Vegas Grand Prix winner — and 19-year-old rookie Kimi Antonelli. Both vehicles were partially disassembled, their chassis exposed except for the engine and primary bodies. After each initial practice session, Mercedes engineers routinely dismantle significant sections of the car to conduct a detailed post-run analysis.

“This review is a required step,” a team guide noted. While four engineers examined every surface of the chassis with practiced precision, three others were engaged in a frame-by-frame review of Antonelli’s on-track footage, comparing the images against telemetry data in real time. The quiet concentration underscored the methodical nature of the work and the seriousness of the environment.

According to the guide, “We dedicate about six hours to reviewing a two-hour race. Understanding every possible variable is essential before refining our strategy.”

The garage includes several designated zones. In the team’s parts storage area — one of the few sections where limited access was permitted — shelves held rows of coded metal containers, along with replacement components and specialized tools. Four spare front wings were positioned for immediate installation should the need arise during the race.

A separate area held dozens of large black bags radiating faint heat. These were tire-warmer bags, used to prepare the tires before a session. F1 tires achieve optimal grip around 212°F. Under Fédération Internationale de l’Automobile (FIA) regulations, teams may preheat them to 158°F up to two hours before running. Mercedes brings 160 tires (40 sets) to every Grand Prix; each set of tires with its warmer is valued at roughly $5,000, amounting to nearly $800,000 in tire-related costs per race.

All teams use standardized Pirelli tires, the sport’s sole supplier.

“Even with identical tires, teams adopt different change strategies,” the guide said, noting that each compound offers a distinct lifespan. He added that the soft compound — the fastest available — averages about 18 laps.

The equipment used throughout the season travels with the team to all 24 race locations. Mercedes transports roughly 100 tons of material for each event, including three cars (two primary and one spare chassis). Approximately 60 percent of the freight moves by sea and 40 percent by air. DHL, the sport’s official logistics partner, oversees the shipments. Races within Europe are handled entirely by ground transport, as all ten teams maintain their primary facilities on the continent; except for Ferrari in Italy, the remaining teams operate out of the United Kingdom.

Teams monitor their freight continuously. Although rare, delays or partial losses do occur. In such cases, teams work with local suppliers to source mechanically compatible parts. Components that are not identical may be used temporarily, provided they meet FIA standards and performance requirements.

Formula One is frequently described as a sport where technology itself is set in motion. Inside the Mercedes-AMG garage, that description felt apt. The space functions not merely as a service area but as a critical command center — the place where performance is shaped, decisions are informed, and the groundwork for competition is laid with quiet, deliberate precision.

BY KYEONGJUN KIM [kim.kyeongjun1@koreadaily.com]